LED – WHAT IS IT?

AND HOW DOES an LED illuminant ACTUALLY WORK?

LED = LIGHT EMMITTING DIODE

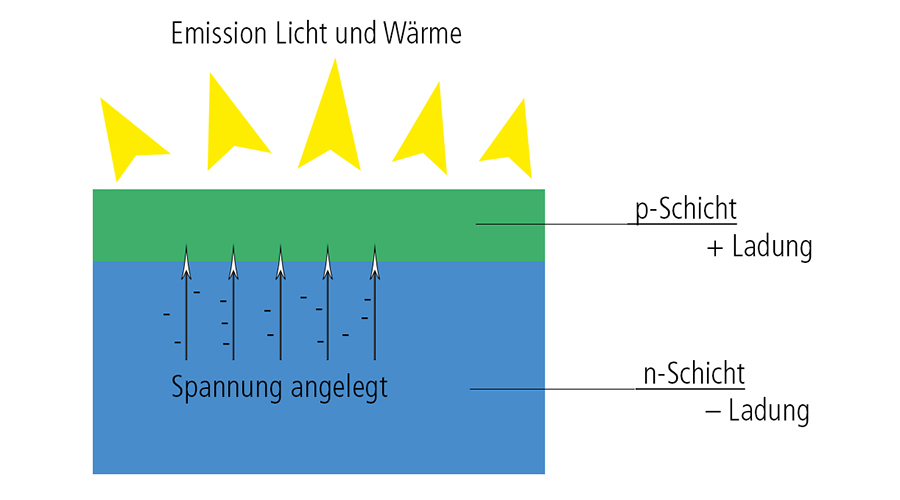

Light emitting diodes consist of 2 layers of semiconductor material with different charges. Semiconductor crystals are neutral, the different charges are generated by the addition of charged atoms such as silicon or boron. The

n-layer has an excess of electrons and is thus negatively charged; the p-layer is positively charged and has so-called electron holes. If both layers are brought together, the charges in a boundary layer balance each other out, NOTHING happens.

If we now apply a voltage, even a very small one is enough, the electrons from the n-layer begin to “jump” into the electron holes of the p-layer. There, the electrons connect with the positively charged atoms and discharge their excess energy in light flashes. This is what we perceive as visible light.

The more voltage we apply, the stronger the effect and the more light is emitted.

This is called the “principle of electroluminescence of a semiconductor”.

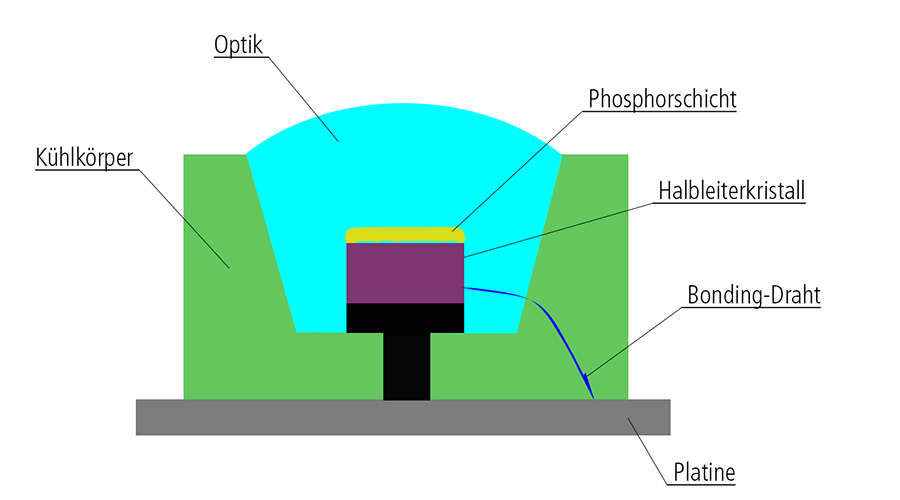

The wavelength of the light emitted varies depending on the material of the semiconductor and the substances added. Typically, however, the wavelength range is very limited – the emitted light is monochrome, so it has only one color. Red, or blue, or green. There is NO white light, but we need it for artificial lighting. We can create this by coating the diodes with a fluorescent layer. The composition of this layer (usually phosphorus) produces different light colors.

THE COOLING BODY

Electroluminescence generates not only light but also heat. Not as much as with a tungsten filament, but enough to damage the sensitive semiconductors. To protect them, they are applied to or enclosed by a heat sink. This guarantees a long service life and, above all, largely constant luminosity with low heat generation.

TYPES OF LED

Basically there are 2 types of LED. “High Power” and “Low Power”. High Power LEDs are those diodes which are operated with more than 10mA. They enable high luminosity in a small space, but are also heat-sensitive and have a shorter service life.

DIP LED

- Dual-in-line-package – the earliest type of light emitting diodes. This LED is soldered to a circuit board with two wires and emits only one wavelength of light. It is often used as a display for electrical devices.

SMD LED

- Surface-mounted device, is still the most common type of LED. Semiconductors and heat sinks form a unit. Diodes are soldered in a circuit onto a circuit board. The semiconductor itself is soldered into the heat sink, this solder joint is heat transfer and electrical connection at the same time. The second electrical component is the so-called bond wire over which the voltage is applied.

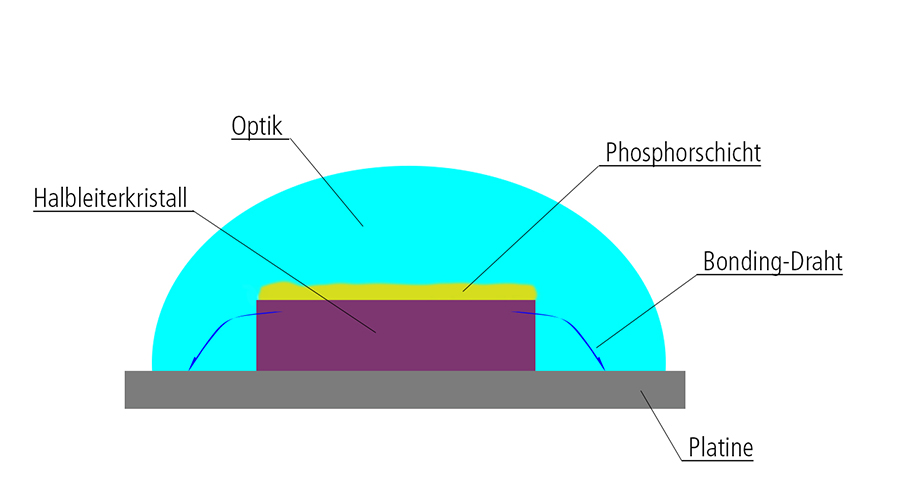

COB LED

- Chip-on-board. With this technology, the semiconductor is soldered directly onto the board in its own package. This can consist of different materials and also serves as a heat sink. Ceramic is a good material because its heat conducting properties are excellent. The voltage is generated by two bonding wires. This technique is becoming more and more popular. SEGULA light sources are now exclusively equipped with COB LEDs.

The COB technology made the development of modern filaments possible. This is not only groundbreaking in terms of technology, but also in terms of design. The patented Soft Filament PLUS provides excellent characteristics and optics! In the SEGULA Soft Line we only use this new filament!